Plaster

Systems at Buffalo Plastering & Architectural Casting

Illustrated

Architecture Dictionary

GFRC

-

Glass Fiber Reinforced Concrete

at Buffalo Plastering & Architectural Casting

Buffalo

Plastering & Architectural Casting, Inc. - Official Website

Using

quarried stone as a building

material

is expensive. Less expensive substitutes have always been

popular. For example, "in the eighteenth century, sand

impregnated paint was applied to wood to look like quarried

stone" (Pieper,

2011).

GFRC

GFRC: At Buffalo Plastering & Architectural Casting, Inc., a substitute for exterior stone architectural sculpture and restoration is a concrete substitute: GFRC - Glass Fiber Reinforced Concrete.

GFRC

is

a thin shell cast material making it lightweight. The

addition of cast glass fibers [material made from extremely fine fibers

of glass] acting as reinforcement creates durability without requiring

embedded steel.

The lightness of GFRC also makes it an efficient and cost effective

material to install. Where many similar products require massive

additional structuring to hold their weight, this lightweight product

can often be supported with only the existing studs and framing in

place.

Recall that the 1901

Pan-American

Exposition buildings in Buffalo - with a few exceptions -

were constructed of wooden frames and walls of plaster reinforced with

cloth:

Plaster systems

Plaster systems: The substitute for interior stone architectural sculpture and restoration is a plaster substitute: plaster systems - plaster reinforced with materials like burlap, horsehair, polymers, or fiberglass.

All the photographs below were taken at Buffalo Plastering in December 2011 with the assistance of the two partners, Gary Bolles and Leo Lysy.

1. Providing the model The client provides the architectural sculpture or restoration model in many possible forms, including:

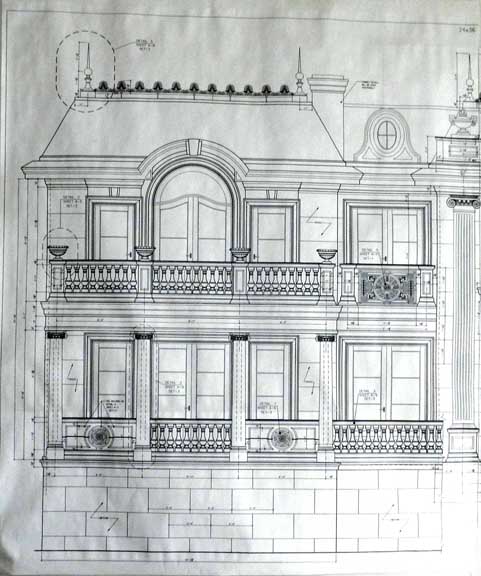

A client may have only an architect's drawing to indicate what's desired, for example in this illustration, rosettes or balustrades. The next step would be to create clay models.  Damaged terra cotta tile from the Ansonia Building. The contract is for four GFRC tiles to be cast. |

|||

2. Creating a mold Most molds are created from rubber.

A rubber mold is formed around

the model. After drying, reinforced cement or plaster is

poured

into the mold. In this illustration, an artisan removes the

rubber mold

from an exterior GFRC (glass fiber reinforced concrete)

panel

after it has hardened.

|

|||

|

3. Casting GFRC GFRC is a thin shell cast material making it lightweight. The addition of cast glass fibers [material made from extremely fine fibers of glass] acting as reinforcement creates durability without requiring embedded steel. The lightness of GFRC also makes it an efficient and cost effective material to install. Where many similar products require massive additional structuring to hold their weight, this lightweight product can often be supported with only the existing studs and framing in place.  A roll of glass fiber, used as a reinforcing product to make thin concrete durable without requiring embedded steel.  Closeup of Glass fiber |

|||

|

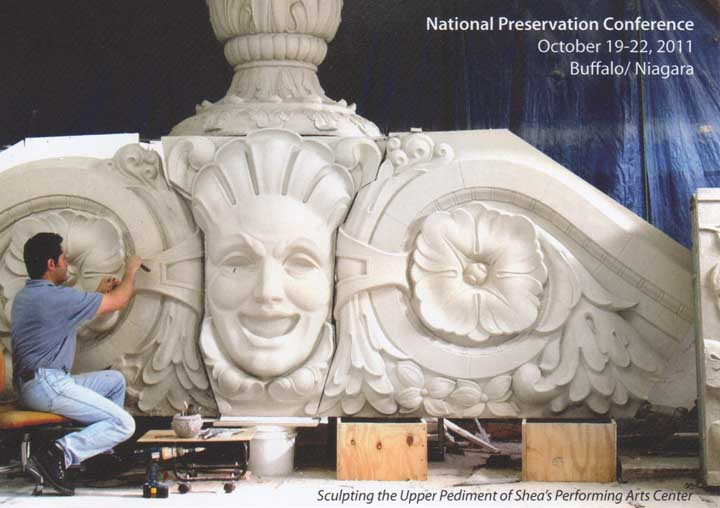

Buffalo

Plastering fabricates columns,

cornices,

domes,

architectural and religious sculpture in both interior

and exterior materials that replicate terra

cotta, limestone, marble,

or travertine.

2011 postcard showing partner/sculptor Leo Lysy chiseling finishing touches on a cast glass fiber reinforced concrete (GFRC) pediment. Photos of the mounted Shea's Performing Arts Center pediment. |

|||

5.

Examples of Cast GFRC

|

|||

Replicated wood carriage and GFRC barrel which is on the table behind the carriage. See next photo:  5' 6" in. long. barrel. |

|||

Buffalo Plastering & Architectural Casting partner/sculptor Leo Lysy  Buffalo Plastering & Architectural Casting partner/business manager Gary Bolles

|

Examples of Buffalo Plastering's work on Buffalo Architecture and History Website: