Buffalo Grain Elevator Preserve - Table

of Contents ............... Grain Elevators - Table of

Contents ,,,,,,,,,,,,,,,,,,,,

Public Art - Table of

Contents

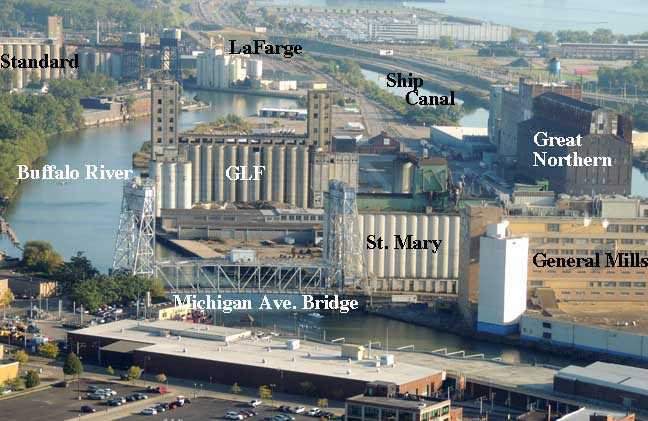

General Mills and St.

Mary's

Elevators

By

Dennis Galucki and Chuck LaChiusa

Center for the Study

of Art, Architecture, History and Nature

On

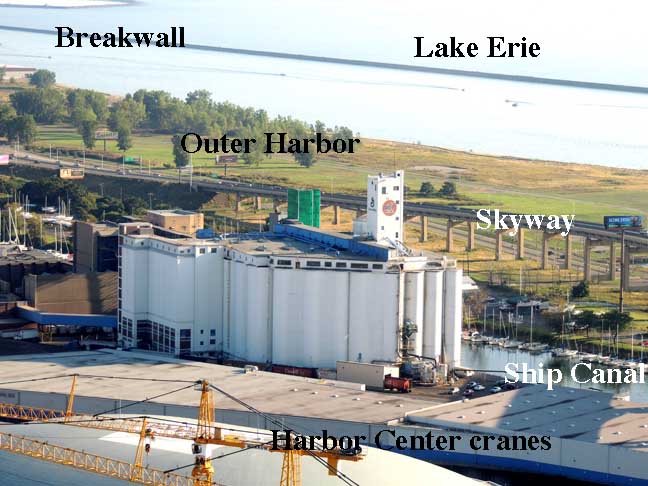

this page, below:

| Frontier

/ Washburn Crosby / General Mills elevators 54

S. Michigan Ave, Buffalo, NY

History of the site:

Main source: HABS:Washburn Crosby Elevator (online July 2016) |

Frontier

/ Washburn Crosby / General Mills Elevators 2013 photo |

| Frontier / Washburn Crosby / General Mills

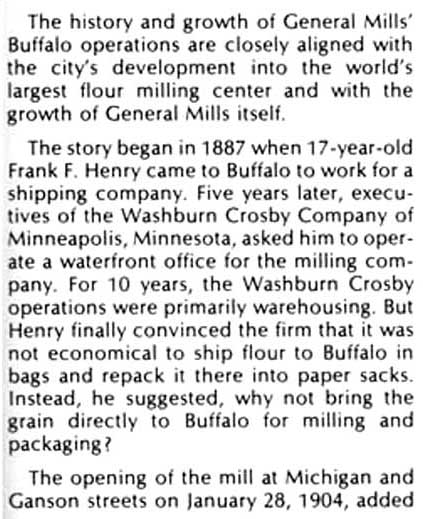

Elevators Reprint Buffalo: Lake City in Niagara Land By Richard C. Brown and Bob Watson. USA: Windsor Publications, 1981, p. 285    |

|

Frontier / Washburn

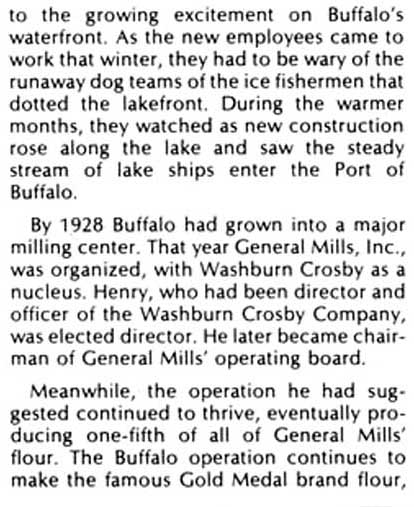

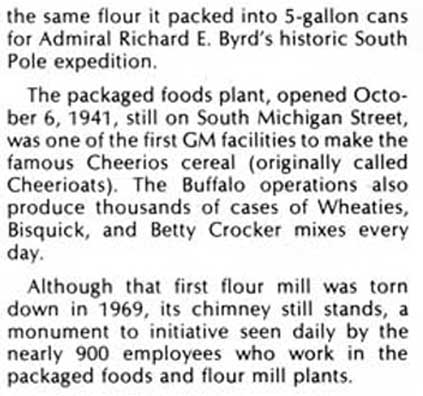

Crosby / General Mills Elevators The large General Mills elevating and milling complex at 54 South Michigan Street began as a small Buffalo-owned elevator company, Frontier Elevator, incorporated by six local businessmen in 1886. The Frontier has a capacity of 4.75 million bushels and was the largest of Buffalo's 21 elevators in operation at the time. In 1903 a new flour milling company came to buffalo from Minneapolis, the Washburn Crosby Company. The mill was built next to the Frontier on the site of the old Dakota Mill that had burned some years earlier. The company's tile storage tanks lacked marine legs. Washburn Crosby made an agreement with Frontier for unloading and transferring grain. In 1907 Washburn Crosby bought out Frontier. In 1928 General Mills was organized in Buffalo with Washburn Crosby as its nucleus. The Buffalo operation has made the Gold Medal brand flour as well as Wheaties, Bisquick, Betty Crocker mixes and Cheerios (originally called Cheerioats). By 1964, General Mills owned O-Cell-O, a manufacturer of synthetic sponges, and Kittinger Furniture. Other elevator additions on the site were constructed of concrete, although the only remaining tile elevator in Buffalo is still part of the complex. See also: HABS (online April 2015)

|

|

Frontier / Washburn Crosby / General Mills

Elevators

Tile Bins Extract from the Nomination to the City of Buffalo for landmarking the Great Northern Grain Elevator At the end of the 1890's, two means for more rigid fireproof construction came from Minneapolis: the tile bin and the reinforced concrete bin. Tile Bin: The tile bin was short lived but conceptually important. Bins were made of tile construction reinforced with steel, a technology that came from the tile-built, steel-rod-reinforced floors and internal partitions used in big cities like Chicago at that time. The dominant system for tile bins was patented in 1895 by the Barnett-Record (Johnson-Record) Company of Minneapolis, Minnesota, and the system was proven in 1899 when a single experimental tank was built and evaluated in Minneapolis. The first phase of Buffalo's Washburn-Crosby (now General Mills) Elevator consists of a set of nine Johnson-Record tile bins. They date from 1903 and were attached to a six-story, brick pier milling building, designed by Buffalo's Reidpath office. Buffalo's Plympton Elevator stood from 1869 until 1902 and was a brick ancestor of the final tile system. Ernest V. Johnson (the Johnson of the John- son Record system and son of George H. Johnson, the pioneer of fireproof elevator construction) constructed the iron and brick elevator in Buffalo. Special interlocking bricks were used with no exterior walling with successful protection against the exterior climate. Banham ((Reyner Banham, "A Concrete Atlantis," p. 134)) described the technology: The basic technology of the system proven by the test bin built in 1899 was by modern standards a hybrid, consisting of a circular wall laid up of two leaves of special square tile. The inner and outer leaves were grouted together without a cavity, and the tensional loads were taken up by hoops of two-inch steel strap between the leaves. Although this system proved entirely satisfactory, to judge from observations made three years later, it was substantially simplified in the improved version commonly employed thereafter. The latter used a single-leaf structural wall made of alternating courses of short and tall tiles; the short ones were hollow troughs into which the steel reinforcing rings were laid and then grouted down solid. Early versions of the simplified system apparently had a layer of glazed tiles lining the inner face of the wall to protect the grain or to prevent it from catching during discharge, but this was deemed unnecessary and these "furring" tiles were transferred to the outer face of the wall to protect the main structure against damage by external fire and weather. For a short period - barely a decade - the developed Johnson system must have been highly acceptable to the trade, for a very large number were built and still stand in their naturally handsome brown-to-purple, salt-glazed color range, a familiar part of the urban scenery of the elevator districts of cities from the Midwest up into Canada and across to the East Coast. |

|

General Mills Elevators

2016 Products:

2016 Operations:

|

Postcard |

| General

Mills Elevator 2004 photos - unless indicated otherwise  2015 photo  General Mills framed by the Skyway - 2004 photo  General Mills on Kelly Island ... - 2004 photo ... Buffalo Ship Canal  General Mills - 2004 photo  General Mills - 2004 photo  General Mills - 2004 photo  General Mills - 2004 photo  General Mills - 2004 photo  General Mills ... 2004 photo ... Silos with mainhouse above  General Mills - 2004 photo  General Mills - 2004 photo  General Mills - 2004 photo  General Mills - 2004 photo |

| General Mills Mural By Nicole Cherry September 1, 2020 photos  View from Michigan Avenue: the foot of Michigan Avenue ... Buildings are part of the General Mills complex ... Note red and white barrier, detailed below:  Behind the barrier and trees: Buffalo River and the site of the Michigan Avenue Wooden Bridge which connected Michigan Avenue and Kelly Island. ... The bridge was demolished in the 1950s after a boat accident badly damaged the bridge.  Note the c. 1903 smokestack, detailed below:  C. 1903 Washburn Crosby Co.   Historic millstones which were used to mill (crush) grain ... For another example, see Williamsville Village Hall   By Nicole Cherry ... Three mural details below:    By Nicole Cherry |

|

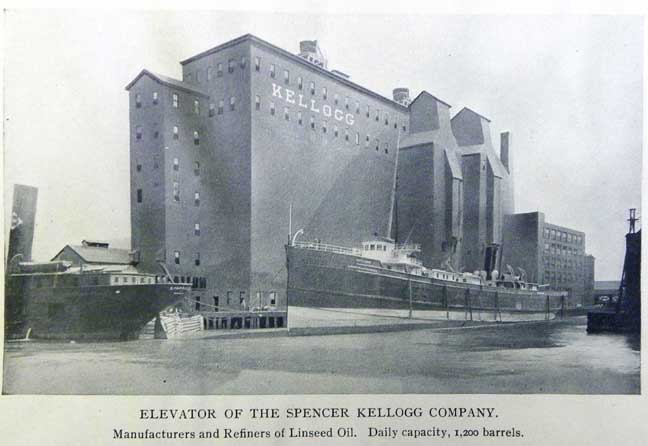

History of the site:

? - Coatsworth wooden elevator built on north side of the slip

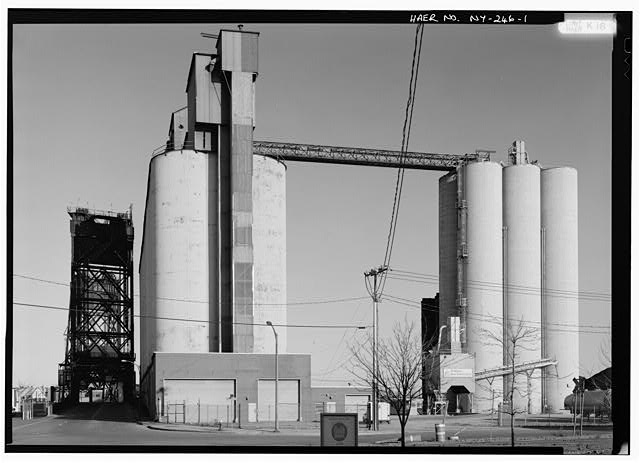

1890s - Spencer Kellogg wooden elevator built on south side of the slip 1893 - Coatsworth burned down 1894 - Replacement Coatsworth built 1903 - New brick Kellogg elevator built 1901-1910? - Kellogg acquired the Coatsworth which became Kellogg "A"; the original Kellogg became Kellogg "B" 1910 - Kellogg "A" (former Coatsworth) replaced with reinforced concrete elevator 1912 - Original Kellogg elevator ("B") demolished and replaced with a single loading bin; the overhead gantry constructed 1923 - Single loading bin augmented by 4 steel bins and one interstitial bin The earliest elevator built on the Wadham Slip (later renamed the Spencer Kellogg Slip), was the wooden Coatsworth Elevator The second Coatsworth Elevator became the Kellogg "A" Elevator. Spencer Kellogg's grandfather began milling linseed oil in 1824 in the Mohawk Valley near Amsterdam, New York. Spencer Kellogg moved to Buffalo and, at age 28, built his first linseed oil mill in 1879. By 1894, he constructed a second mill, giving him a total of 36 presses, making his the largest linseed oil plant in the U.S. The company existed in Buffalo from 1879 to 1961, growing from a modest one-man operation to become a diversified international enterprise operating in eight states and several foreign countries. The elevator consists of a large set of bins joined at the top through a 1917 transfer system to a small collection of bins on the south, with a gap of perhaps 150 feet between. The reason for this odd setup is that there was once a slip here underneath the transfer system (see photo showing the slip). Two vessels could be handled at the same time. Instead of storing grain, the elevators now store cement.

See also:Built in America

|

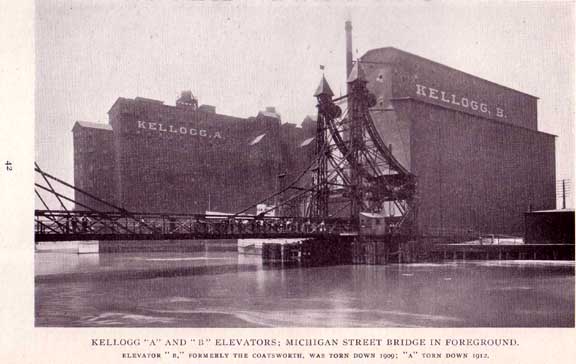

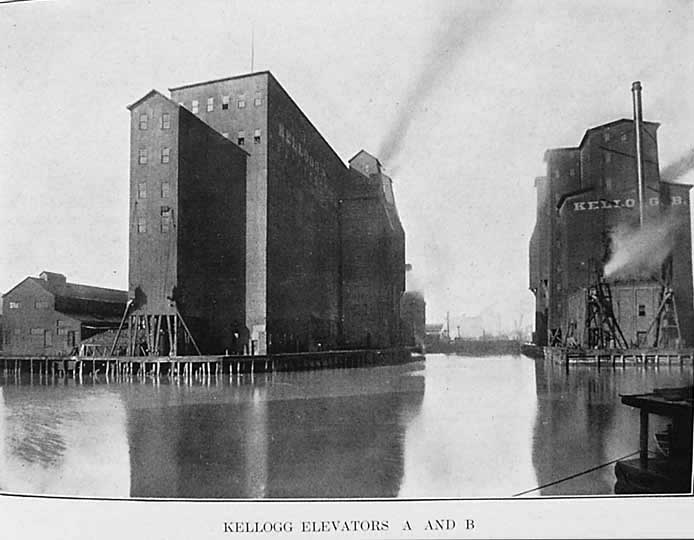

St.

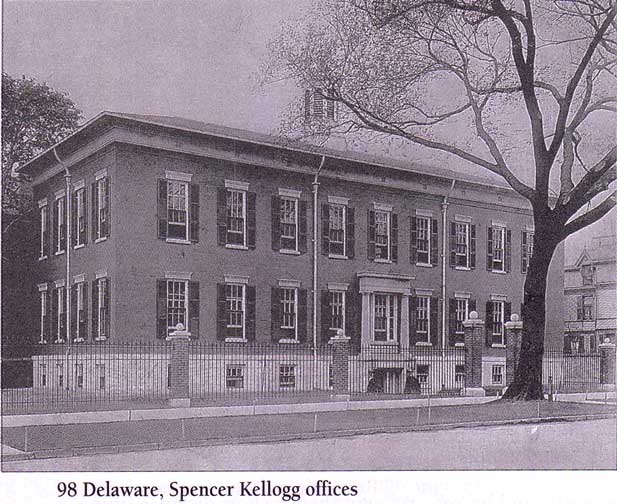

Mary's Cement Elevator 2013 photo  2015 photo  2015 photo  Kellogg "A" and "B" Elevators; Michigan Street Bridge in foreground. "A" was demolished in 1912. ... Elevator "B" which had replaced the Coatsworth elevator in 1894 was demolished in1909. Source: "The Picture Book of Earlier Buffalo," Frank H. Severance, ed. Buffalo Historical Society Publications, Vol. 16, 1912, p. 42  Kellogg "A" and "B" Elevators; Michigan Street Bridge in foreground. "A" was torn down 1912. ... Elevator "B" was torn down in 1912. Source: "A History of the City of Buffalo," published by the The Buffalo Evening News, 1908  Demolished 1912. Spencer Kellogg Elevator / Schaefer Brewing / St. Mary's Cement Elevator  Spencer Kellogg & Sons, manufacturers of linseed oil, bought the Barnard property (98 Delaware Avenue) in 1910 and enlarged it, keeping the original Colonial design. Kellogg & Sons was the first business to move to Niagara Square. The house was razed and replaced by a parking lot in January 1960.  Eastern elevations ... 2014 photo. Brick building: General Mills flour mill ... Center: St. Mary's ... Right: Michigan St. Bridge 1910

- Kellogg "A" (former Coatsworth) replaced with reinforced concrete

elevator ...

1912 - Original Kellogg elevator ("B") demolished and replaced with a single loading bin; the overhead gantry constructed 1923 - Single loading bin augmented by 4 steel bins and one interstitial bin  Spencer Kellogg Elevator, 389 Ganson Street. The elevator (left) consists of a large set of bins joined at the top through a 1917 transfer system to a small collection of bins on the south, with a gap of perhaps 150 feet between. The reason for this odd setup is that there was once a slip here underneath the transfer system . Two vessels could be handled at the same time. Source: HABS St. Mary's Cement Elevator In 1917, a slip ran between the two elevators. To connect the two, an overhead bridge - a 1917 transfer system - was built. Two vessels could be handled at the same time.  St. Mary's Cement Elevator, gantry and loading bins - 2004 photo  St. Mary's Cement Elevator - 2004 photo  St. Mary's Cement Elevator - gantry and loading bins ... 2004 photo  St. Mary's Cement Elevator - Loading bins and gantry ... 2004 photo  St. Mary's Cement Elevator - 2004 photo |