Williamsville Water Mill - Table of Contents .......................... Williamsville - Table of Contents

Williamsville Water Mill

36 Spring Street, Williamsville, NYOn this page, below:

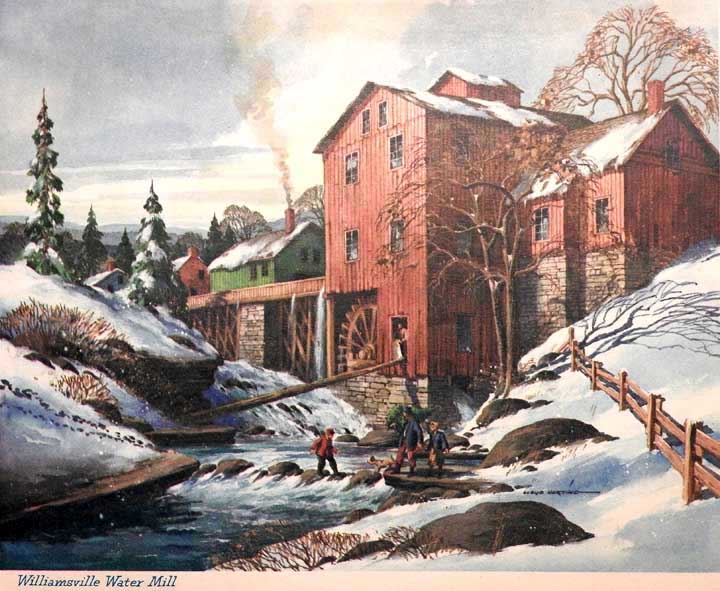

Status  "This

stately silhouette represents the hopes

and struggles of the community’s earliest settlers. The watermill

started its operation in 1811 and functioned as a flout [flour?] and

grist mill until the 1820s when it converted into a cement business

with the building of the Erie Canal and went back to a flour and grist

mill in the mid-1880s. The mill was built by Jonas Williams

, an early settler and the namesake of the village. The mill was owned

and operated by Phillip Klein, Edward Jacobi Sr., and Edward Jacobi Jr.

from 1902 to 1947. Then in 1947, Mr. Niederlander and his wife Mrs.

Grace Miller Niederlander took over the mill and restored it. The mill

then fell into disrepair and the village bought the mill in 2005 and

saved it from decay. The village is restoring the mill and plans to

sell the structure to Sweet Jenny’s ice cream shop. It will remain the

permanent home of the Williamsville Farmers Market." - Williamsville

Historic Preservation Commission (online October 2017)

Mill: A building equipped with machinery for grinding grain into flour. Grist mill: A mill for grinding grain. |

Mill building Left: water mill ... Right: barn ... This area has been the site of various buildings. See the Chronology at the bottom of this page.  Jonas Williams built a permanent grist mill on the west bank in 1811. He was also responsible for building a tannery, distillery, and dams and raceways to power his mills. The pioneer settlement of Williams Mills developed around these mills.   |

Raceway

- View from Glen Park Greeting card courtesy of Dennis Dempsey ... Mill race: the channel carrying the swift current of water that drives a mill wheel ... The mill race extends into the mill and as an overshot, pumps the water wheel The

gristmill's workings were powered by water from Ellicott Creek via a

mill race.

Raceway/mill race: a narrow channel for water Undershot: driven by water passing from below, as a water wheel. Overshot: operated by water that flows over the top from above: an overshot water wheel Millstone: Each of two circular stones for grinding grain  Glen Park raceway beginning: the raceway originates in Ellicott Creek, on the other side of Main Street  Glen Park: Mill race on the side of the barn  Glen Park: Mill race (raceway) which was reconstructed c. 2017 ... Mill race: the channel carrying the swift current of water that drives a mill wheel  Glen Park ... Mill race on the side the barn ... Detail below:  Barn ... c. 2016 reconstructed raceway ... 1905 vertical concrete presure chamber ... See Bero Architecture P.C., Historic Structure Report - Williamsville Water Mill for more information |

Raceway - View from Mill site Raceway located behind the Onondaga limestone wall ... Historically, there were other buildings on the lawn area   Mill race which was reconstructed c. 2017 |

Milling operation Historic lower millstone in front of Williamsville Village hall ... Millstone: Each of two circular stones for grinding grain ... Detail below:  Lower millstone ... Note millstone grooves where the wheat fell after being ground into grist, dropped into a second elevator, and was raised again to the upper floors where it went through additional machinery to dry and sort it by grade. The final product then dropped into produce bins on the first floor, ready for sale or packing and shipping.  Millstone on the Mill site between the Mill and the barn  Inside the mill in the room that houses two millstones and hopper (to the right, out of the photo)   Hopper above two millstones ... "The

basic design was a hewn timber frame enclosing an overshot water

wheel whose power was harnessed through a series of gears to

operate two sets of mill stones

as well as a series of elevators which raised the incoming

unprocessed

material to the top floor, where it passed by gravity through a series

of cleaning operations before dropping onto the millstones for slow

grinding. The resulting product left the millstones through grooves,

dropped into a second elevator, and was raised again to the upper

floors where it went through additional machinery to dry and sort it by

grade. The final product then dropped into produce bins on the first

floor, ready for sale or packing and shipping." - Bero Architecture

P.C., Historic Structure Report - Williamsville

Water Mill

Hopper:

A container for a bulk material such as grain, rock, or

trash, typically one that tapers downward and is able to discharge its

contents at the bottom. Cf.. Perot

Malting Elevator hopper

|

|

The paddle wheel was attached to a shaft which was, in turn, attached to the centre of the millstone called the "runner stone". The turning force produced by the water on the paddles was transferred directly to the runner stone, causing it to grind against a stationary "bed", a stone of a similar size and shape. This simple arrangement required no gears, but had the disadvantage that the speed of rotation of the stone was dependent on the volume and flow of water available and was, therefore, only suitable for use in mountainous regions with fast-flowing streams. This dependence on the volume and speed of flow of the water also meant that the speed of rotation of the stone was highly variable and the optimum grinding speed could not always be maintained. Vertical wheels were in use in the Roman Empire by the end of the first century BC. Classical British and American mills Although the terms "gristmill" or "corn mill" can refer to any mill that grinds grain, the terms were used historically for a local mill where farmers brought their own grain and received back ground meal or flour, minus a percentage called the "miller's toll." Classical mill designs are usually water-powered, though some are powered by the wind or by livestock. In a watermill a sluice gate is opened to allow water to flow onto, or under, a water wheel to make it turn. In most watermills the water wheel was mounted vertically, i.e., edge-on, in the water, but in some cases horizontally (the tub wheel and so-called Norse wheel). Later designs incorporated horizontal steel or cast iron turbines and these were sometimes refitted into the old wheel mills. The distance between the stones can be varied to produce the grade of flour required; moving the stones closer together produces finer flour. The [farmer's] grain is lifted in sacks onto the sack floor at the top of the mill on the hoist. The sacks are then emptied into bins, where the grain falls down through a hopper to the millstones on the stone floor below. The milled grain (flour) is collected as it emerges through the grooves in the runner stone from the outer rim of the stones and is fed down a chute to be collected in sacks on the ground or meal floor. A similar process is used for grains such as wheat to make flour, and for maize to make corn meal. |

|

Chronology East side mill: later Dodge Mill West side mill: later Williamsville Water Mill Information culled from Bero Architecture P.C., Historic Structure Report - Williamsville Water Mill (online October 2017) 1811 – First construction of a gristmill and/or sawmill on the mill site, by Jonas Williams, as a supplement or replacement for an earlier grist/sawmill on the east side of the creek. The original west side sawmill was located in the space between the present mill and the mill house 1814 – Mill sold to Juba Storrs & Co. 1819 – 1825 - Natural cement rock discovered in Williamsville, quarried and ground for use in Erie Canal construction. Original cement manufacturing likely took place in the east side mills. 1827 – Mill property sold to Oziel Smith, along with mills on the east side. The mill operation on the west side was significantly expanded to accommodate the natural cement business. This may have been the time of construction of the existing mill building. 1830 – 1866 – Mill had a series of owners including Benjamin Hershey, Timothy Hopkins and John S. King. Operations included the manufacture of natural cement as well as saw milling. During this time the mill house and the John S. King House were built. As of 1854 the mill house was used as part of the sawmill. 1866-1905 – Mill owned by Benjamin Miller and later his son Edward B. Miller. A freestanding office building was built in the front of the mill, used as Edward Miller’s Justice of the Peace office and possibly as the mill office as well.1880s – Natural cement manufacturing discontinued, and the main mill converted to gristmill use. Sawmill continued in operation. 1903 – Sawmill and adjacent flume collapsed into creek due to ice build-up. Flume was reconstructed, but not the sawmill. 1904 –Edward B. Miller died. 1905 – Property sold to Joseph Jacobi, with later partners Ferdinand Senf and Charles Klein. c. 1908 – 1910 – Major overhaul of milling operations, including the addition of a basement level turbine to power the milling operations in winter. Present millstones, gearing equipment and other mill machinery were installed at this time. Cider mill began operation in north wing. 1947 – Property purchased by Daniel and Grace Niederlander. The south exterior of mill building and mill house restored with replacement siding. King house moved to the site in 1949. Property continued in use as a “historic mill”, with some milling activity, seasonal cider making, and a gift shop, through 2003. Mill operations continued with occasional demonstrations of milling equipment through 2003. |