Marine A - Table of Contents ........... Grain Elevators - Table of Contents

2013 color photos

Interior - Marine "A" Elevator

105 Childs Street in the First Ward in Buffalo, NY

Part of Silo City

The main source of information about Marine "A" is HABS (online April 2013)

| Built: |

1925 |

| Designer: |

T. D. Budd, James Stewart & Co. Supervising engineer: A. E. Baxter Engineering Co. |

| Features: |

1.

Rather than raising the bins on a full bin slab above basement columns

which bore the weight of the structure, the design carried the bin

walls down to the foundation slab. Within each bin, a full width conical

hopper is supported on pilasters In this design, the hopper bottom only has to support the weight of the grain in the hopper. The weight of the grain above the hopper is transfered to the side wall of the bin. 2. This is an early example of all concrete slip formed workhouse construction. |

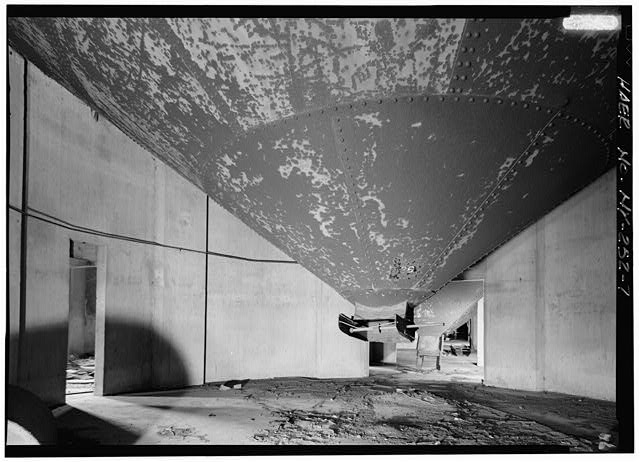

Interior In this photograph, most of the steel hopper has been cut away by thieves. At the bottom of each bin is a full width conical hopper supported on 8

pilasters. The pilasters are

placed equidistantly about the circumference of the

bin wall. They extend to a height of 13' above the foundation slab.

An annular channel section "compression girder" runs around the inside circumference of the bin walls and rests on 4" x 6" I-beams. The conical steel plate hopper is hung from the compression girder. To ensure a tight fit, the steel hopper is mortared to the wall.  Grain hoppers in central corridor. Photographer: Jet Lowe, 1990 found on HABS (online March 2013) Rather than raising the bins on a full bin slab above basement columns

which bore the weight of the structure, the Marine "A" design carried the bin

walls down to the foundation slab. Within each bin, a full width conical

hopper is supported on pilasters, shallow rectangular columns projecting only slightly from a wall.

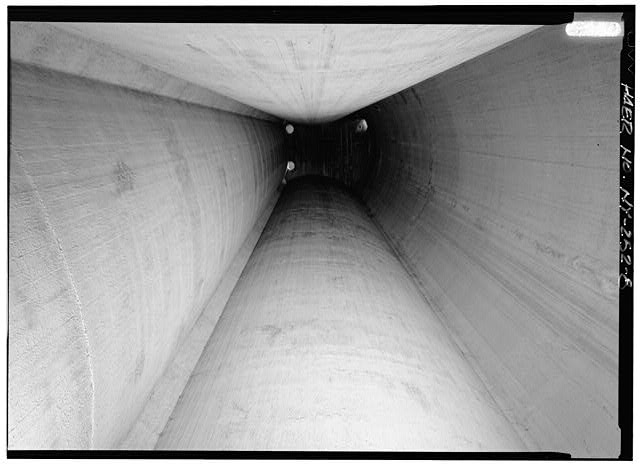

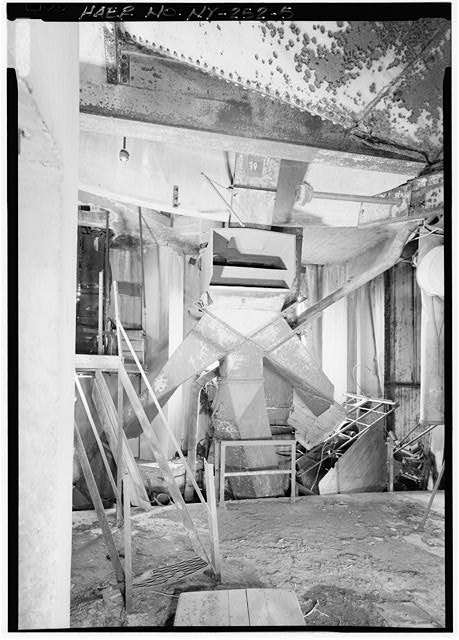

In this design, the hopper bottom only has to support the weight of the grain in the hopper. The weight of the grain above the hopper is transfered to the side wall of the bin. The hoppers are angled at 37 degrees. In this design, the hopper bottom only has to support the weight of the grain in the hopper. The weight of the grain above the hopper is transfered to the side wall of the bin.   There is a hopper at the bottom of each bin in each section. Hoppers are not visible because thieves cut away most of each hopper for scrap metal.  Interspace/interstitial bin looking up. Photographer: Jet Lowe, 1990 found on HABS (online March 2013) Interspace/interstitial bins are smaller bins between main bins. Interstitial bins are not visible on the exterior. Each interstitial bin has its own hopper at basement level.  Most of the hopper has been cut away for scrap metal  Looking up into silo where most of the hopper has been cut away. 2 trap door holes are where grain in dropped into the silo from above.  Looking up into silo where most of the hopper has been cut away.  Two sides of a lofter leg with exposed buckets on one side. Some of the rectangular steel enclosure has been cut away.  One side of a lofter leg with exposed buckets. Some of the rectangular steel enclosure has been cut away.  Steel buckets on lofter leg (usually enclosed in steel).  Rail chutes and horizontal conveyor system. Photographer: Jet Lowe, 1990 found on HABS (online March 2013)  Broken horizontal conveyor system  Distribution chutes at end of central conveyor system . Photographer: Jet Lowe, 1990 found on HABS (online March 2013) |

|

Rail shipment

Though the Marine Elevator Co. did not anticipate unloading substantial amounts of grain shipped by rail, facilities were provided to transfer from cars to the new elevator. Four tracks entered the car shed vat the southwest corner of the elevator and between each pair of tracks a carpuller was installed for spotting boxcars over the receiving hoppers or under the car loading spouts. Two pairs of manually-guided Clark automatic power shovels scraped the grain out of the cars and into the 1,000-bushel receiving pits located under the two tracks nearest the elevator.

- HABS, p. 18 (online March 2013)

|