Building Materials - Table of Contents.......................... Illustrated Architecture Dictionary

Pigmented structural glass: Sani

Onyx, Carrara Glass, Vitrolite

History:

In 1900, the Marietta Manufacturing Company claimed to be the first producer of pigmented structural glass, rolling the first sheet of a "substitute for marble," Sani Onyx. The company advertised "Sani-Onyx" as an easy-to-clean, germ-free surface.

Penn-American Plate Glass Company quickly joined its ranks, manufacturing white and black Carrara Glass around 1906. Penn- American Plate Glass no doubt selected the name "Carrara" for the white glass's close resemblance to the white marble of the Carrara quarries of Italy. Later, new colors were added. It was popularly used in the 1920's to 1940's for exterior cladding on storefronts, service stations, movie theaters, and automobile dealerships. Carrara® was also used for interior clean surface areas such as hospital operating rooms, hotel lobbies, restaurants, kitchens, and bathrooms.

During the early 1930's, Libby-Owens-Ford Glass purchased the Vitrolite Company and in 1935 sponsored a "Modernize Main Street Competition" with $11,000 in cash prizes that drew over 3,000 entries for a wide variety of storefronts. By the end of the decade, Vitrolite was as much a storefront fixture as awnings.

Although Vitrolite and Carrara Glass eventually became synonymous with vivid color, structural glass originally came only as black or white.

Although as many as ten companies eventually produced structural glass, its manufacture required major investment. The Vitrolite plant, for example, covered eighteen acres outside Parkersburg, West Virginia. The manufacturing process involved superheating pigment and glass ingredients to 3,000 degrees F, adding fluorides to the molten mix, and then rolling the vitrified glass into sheets of the desired thickness. As the sheets cooled for as many as five days, the fluorides crystallized throughout the glass and rendered it opaque. The final luminous finish was achieved by flame polishing or additional rolling with fine sand.

The glass could be curved and colored to fit the streamlined look of these twentieth century styles and was often applied to older buildings in an attempt to update them. It was generally 11/32" or 7/16" thick and was applied over masonry or plastered walls with an adhesive masti. Besides the easy maintenance of Carrara Glass, it was favored for its brilliant color and durability. Exterior commercial facades were the most common surfaces for the glass, but interior walls and counters were also covered with it.

Structural glass received a major boost in 1913 when architect Cass Gilbert clad the restrooms of the Woolworth Building, then the world's tallest structure, in Carrara Glass. But into the 1920s, Vitrolite and its sisters were promoted as utilitarian surfaces for bathrooms, laundries, and kitchens. Furniture makers recommended Sani-Onyx table tops doused with cool water for rolling pastry, while Maytag used Vitrolite-lined tubs as a selling point for its washers.

|

Structural Glass and Art Deco The dramatic growth and popularization of the early 20th century Art Deco and Moderne architectural styles were fueled, in part, by technological advances in the building materials industry. New products, such as stainless steel and plastics, enlarged the realm of architectural design. The more traditional materials, on the other hand, quickly developed fresh, innovative forms and uses. For example, the architectural glass industry became especially creative, introducing a series of new glass products known as structural glass. Used predominately for wall surfacing, these now familiar products included

The versatility of pigmented structural glass contributed to its popularity. Not only could the material be applied to both the exterior and interior, the glass could he sculptured, cut, laminated, curved, colored, textured, and illuminated. Often applied directly over existing architecture to remodel older buildings, as well as in new construction, a veneer of pigmented structural glass had the ability to define a building's architectural character as new and up-to-date. Pigmented structural glass also complemented the period's silvery metal accents and affinity for slick, shiny surfaces. By the second decade of the 20th century, consumers viewed pigmented structural glass as an inexpensive substitute for marble counter tops, table tops, wainscoting, and restroom partitions.

|

Sources:

- The Preservation of Historic Pigmented Structural Glass (Vitrolite and Carrara Glass)

- The Preservation of Historic Pigmented Structural Glass (Vitrolite and Carrara Glass) Color illustrations

- Rosemary Thornton, Structural Pigmented Glass Part 1

Examples from Buffalo:

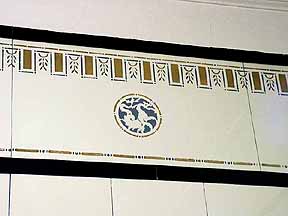

- Illustration above: Bathroom - John W. Cowper House

- Bathroom - David Wallace House

- Exterior black and white - Caffé Lococo, 369-372 Washington Street Demolished

Other examples:

- Exterior green - Positively Main Street façade, 773 Elmwood Avenue

- Christopher Nicholas Brown, The Case of the Missing Vitrolite: A Cautionary Tale of Historic Preservation