American Elevator - Table of Contents .............. Grain Elevators - Table of Contents

Workhouse and Silos

American Elevator / Russell-Miller Milling Company Elevator / Peavey Co. Elevator

87 Childs Street in the First Ward in Buffalo, NY

Part of Silo City

| Built: |

1906; annex: 1931 |

| 1906 construction co.: |

James Stewart Company |

| Original owner and function: |

The founding

company, American

Malting, was created in August 1897, to consolidate a large number of

small malt houses under one combine. The trust was established to sell

prepared malt to brewers more cheaply than they could purchase barley

alone. The Volsted Act (Prohibition) ruined the business. |

| Second owner and function: |

In 1921, the

elevator was taken over by the Russell-Miller company who used the mill

to produce its Occident-brand flour. By the late 1920s, the

company owned 135 country elevators and three terminal elevators

including the American. |

| Third owner: | In

the early 1950s, Russell-Miller was bought out by Peavey Corporation,

the sixth largest grain dealer in the world. Peavey improved the

elevator and made the mill the world's largest pneumatic flouring

processor. |

| Features: |

|

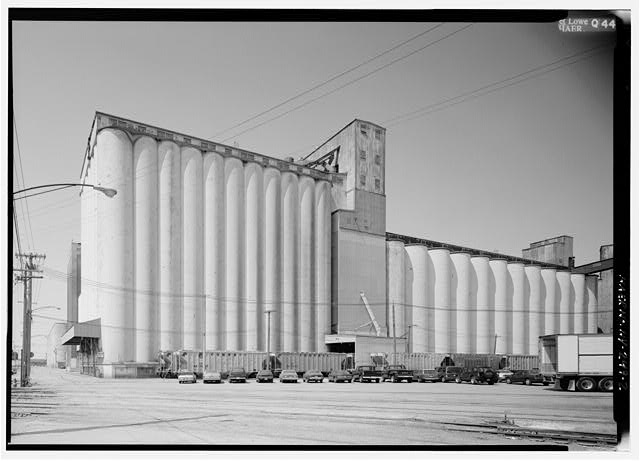

Elevator - Where grain was stored View north. American: Left (gray): flour mill ... Center: truck depot ... Right: elevator annex  East elevation. Photo source: 1994, by Jet Lowe, found on HABS (online March 2013) Left bay: Annex, added in 1930-31 by owner Russell-Miller company which used the mill to produce its Occident-brand flour.

Center: Workhouse Right bay: Original 1906 storage bin area: 48 main cylindrical bins arranged in 4 rows of 12. The inner diameter of each bin is 24'-10". Three rows of eleven interspace bins - with 8" thick walls - are located between the main bins.  Photo taken March 2013 Left (south) annex: "The last major development on the site came in the early 1930s with the addition of an annex

to the south of the existing elevator where it abutted the workhouse.

The annex was built by Monarch Engineering to the in-house design of

H.R. Wait; the work was carried out for the American Elevator and

Warehouse Company, a division of the Russell Miller Company.

The plans were drawn in November of 1930, and the elevator was

operational by the fall of the next year. The bins were built by slip forming above

a conventionally constructed basement and bin slab. It is likely

that the system of threaded jacking rods favored by the Monarch Company

was probably used in bin construction. The bins provide 1,400,000

bushels of storage. The main bins are 20' in inner diameter ... fifteen

3 x 5 interspace bins." - Source: HABS, p. 6 (online April 2013)

Left (south) annex: "Elevating machinery, distributor, and spouting system are in the mainhouse, while storage is in annex bins connected to the mainhouse by external spouts and conveyor systems. In the latter system, grain is moved from the mainhouse to the annex bins by an overhead horizontal conveyor belt with a tripping device that directs it into the designated bin. Grain is moved from the annex bins to the mainhouse on a horizontal conveyor belt below the bins." - Encyclopedia of the Great Plains (online March 2013) Right side 1906 bins: The Elevator was the first in Buffalo built of reinforced concrete, and is thought to be the first in the nation raised by slip forms into which concrete was continuously poured. For more information, see Reinforced Concrete Grain Elevators.  South and east elevations TEXT |

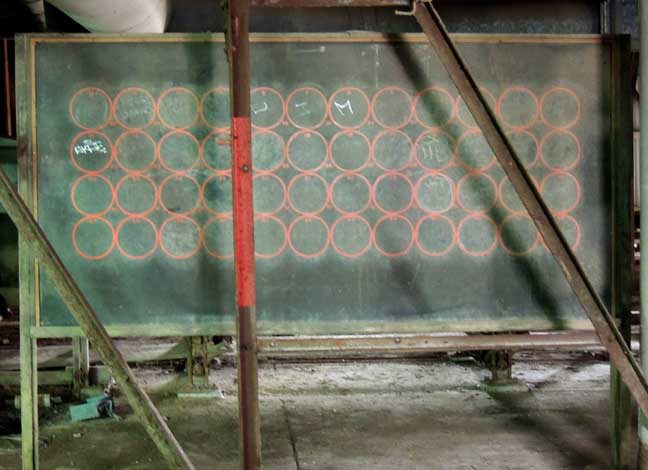

| Workhouse - How grain was moved In the HABS research articles on Buffalo's grain elevators, "workhouse" is used instead of "mainhouse."  Mainhouse / Workhouse Workhouse/ Headhouse/ mainhouse: "The workhouse contains the lower floors, while the headhouse (cupola) consists of two to five upper stories. The workhouse name is derived from the fact that much of the receiving and unloading operations take place on the work floor of the first story, where the elevating (lifting) process begins. The headhouse is so named because the head drive of the vertical conveyor system is located there. The workhouse and the headhouse are collectively referred to as the mainhouse." - Encyclopedia of the Great Plains (online March 2013)  Roller and belt on horizontal conveyor belt for moving grain  Tripper for distributing grain into silos on floor below  Large blackboard with diagram of silos used by workers to track grain in silos  Headhouse  Two loading spouts in the workhouse |

Overhead Conveyor Gallery to Perot Elevator - How grain was horizontally conveyed from American Elevator Left: American Elevator elevator and marine leg... Center: Standard Elevator located across the Buffalo River ... Center: Overhead Conveyor Gallery from American Elevator to Perot Elevator Right: Perot Malting Elevator Note overhead conveyor gallery between American and Perot. Grain needed by Perot for malting barley for beer was

horizontally conveyed from American on the overhead conveyor

gallery.

This occurred only after Russell-Miller bought the American and converted the American Malting operation to flour milling. When the elevator was first owned by American Malting, it and Perot were competitors, and Perot had to depend on the railroad for shipment and delivery.  Horizontal conveyor belt in overhead conveyor gallery between American Elevator and Perot Elevator |