Marine A - Table of Contents ........... Grain Elevators - Table of Contents

EXTERIOR -Marine "A" Elevator

105 Childs Street in the First Ward in Buffalo, NY

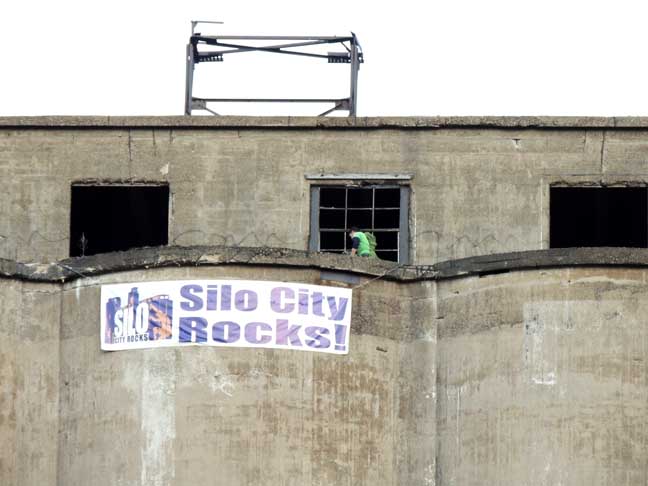

Part of Silo City

The main source of information about Marine "A" is HABS (online April 2013)

| Built: |

1925 |

| Designer: |

T. D. Budd, James Stewart & Co. Supervising engineer: A. E. Baxter Engineering Co. |

| Original owner: | The

Buffalo-based Abell family built the original Marine Elevator about

1870 beside the Hatch Slip at its junction with the Buffalo River

downstream of the Michigan Street Bridge. There was little space for expansion, so Harold L. Abell acquired the undeveloped site at 105 Childs. Upon completion of the building at 105 Childs, the old elevating complex was known as "Marine B." Marine "A", built as a transfer elevator, had a very short active life. It was constructed in 1925 and because it didn't have a mill associated with it (although one had been planned) , the elevator fell victim to the demise of the industry during the 1960s when the transshipment business that was prevalent in Buffalo collapsed. |

| Construction cost: |

$250,000 in 1925 ($3,238,505 in 2012 dollars) |

| Features: |

1.

Rather than raising the bins on a full bin slab above basement columns

which bore the weight of the structure, the design carried the bin

walls down to the foundation slab. Within each bin, a full width conical

hopper is supported on pilasters In this design, the hopper bottom only has to support the weight of the grain in the hopper. The weight of the grain above the hopper is transfered to the side wall of the bin. 2. This is an early example of all concrete slip formed workhouse construction. |

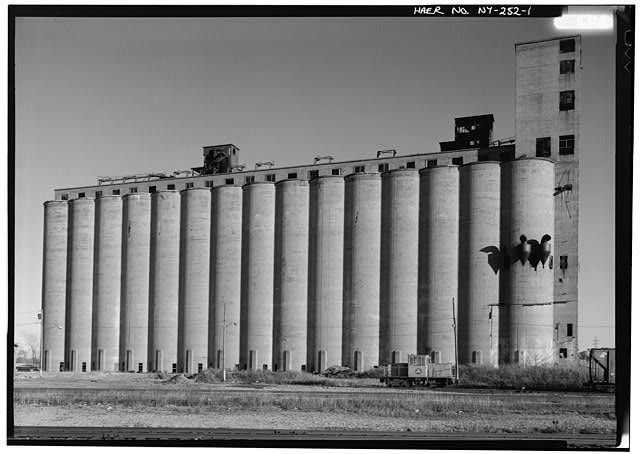

Exterior - West elevation Left: Lake & Rail Elevator ... Right: Marine "A"  Looking east. Note all concrete slip formed workhouse at right of the building. "The workhouse contains the lower floors, while the headhouse

(cupola) consists of two to five upper stories. The workhouse name is

derived from the fact that much of the receiving and unloading

operations take place on the work floor of the first story, where the

elevating (lifting) process begins. The headhouse

is so named because the head drive of the vertical conveyor system is

located there. The workhouse and the headhouse are collectively

referred to as the mainhouse." - Encyclopedia of the Great Plains (online March 2013)

Looking east from rail yards on Childs St. Photographer: Jet Lowe, 1990 found on HABS (online March 2013) The reinforced concrete workhouse at the southeast end of the building (right side of the illustration) extends to a height of 190'. All workhouse walls are 8" thick.  Looking east from rail yards on Childs St. Note top back of the marine leg in top center of the photo. The marine leg faces the Buffalo River on the other side of the image.  Top: Back of one of two the marine legs Windows: Cupola Bottom: Silos  One of the two who prepares to rappel down the elevator during Boom Days on April 6, 2013. See Buffalo Rising photo (online may 2013). Plans are being carried out to turn the elevator into a rock climbing center. Rappel (in mountaineering): the act or method of moving down a vertical face by means of a double rope secured above and placed around the body and paid out gradually in the descent.  Upper left: Top back of one of two marine legs ... Right: Reinforced concrete workhouse.   South east corner   Note exposed rebar used to reinforce the concrete. |

|

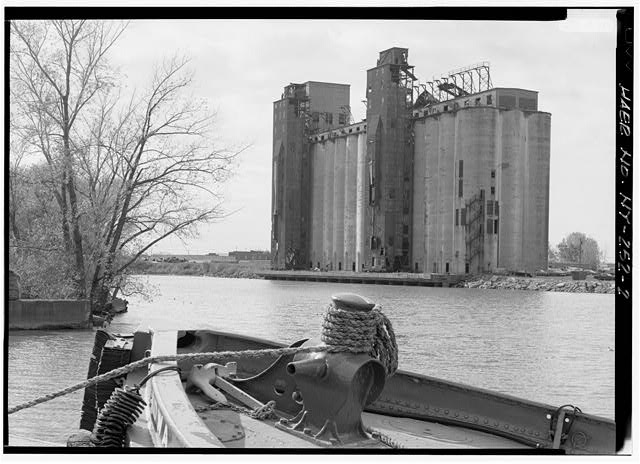

Exterior - East elevation

Looking south. Photo source: 1990, by Jet Lowe, found on HABS (online March 2013) Two movable marine towers ("marine legs") constructed of sheet metal cladding over a structural steel framework.of structural steel. Each marine tower traveled along the dock on 20 pairs of wheels over four heavy rails. Once grain had been raised to the top of the marine tower it descended by gravity through a weighing apparatus (scale) prior to reelevation by the internal main lofter. Lofting legs/ lofters are internal legs for the transfer of grain from the lower to the upper systems of horizontal conveyors. Each marine lofter featured four rows of 14" x 8", 8" deep buckets staggered on 13" centers and attached to a 60" eight-ply rubber belt. A 200 hp motor was located at the head floor of the marine tower. The marine lofters discharged through a traveling spot into the hoppers of continuous V-sprouts atop the roof of the cupola over the main storage bins.   One of two marine legs on the Buffalo River dock.  Detail - marine leg in above photo  Other marine leg  Marine leg puller. Steel cable from this leg puller would be connected to the movable marine leg. Steam energy would power the marine leg puller from one hold in the ship to another hold.

Loading a ship using a dock spout.

Photo source: 1990, by Jet Lowe, found on HABS (online March 2013) For transshipping grain to vessels transiting to the New York State Barge Canal or the Canadian Welland Canal routes, Marine "A" was initially equipped with two dock spouts located at the north and south ends of the elevator, each loading spout designed to handle up to 30,000 bu//hour.  |

|

Rail shipment

Though the Marine Elevator Co. did not anticipate unloading substantial amounts of grain shipped by rail, facilities were provided to transfer from cars to the new elevator. Four tracks entered the car shed vat the southwest corner of the elevator and between each pair of tracks a carpuller was installed for spotting boxcars over the receiving hoppers or under the car loading spouts. Two pairs of manually-guided Clark automatic power shovels scraped the grain out of the cars and into the 1,000-bushel receiving pits located under the two tracks nearest the elevator.

- HABS, p. 18 (online March 2013)

|